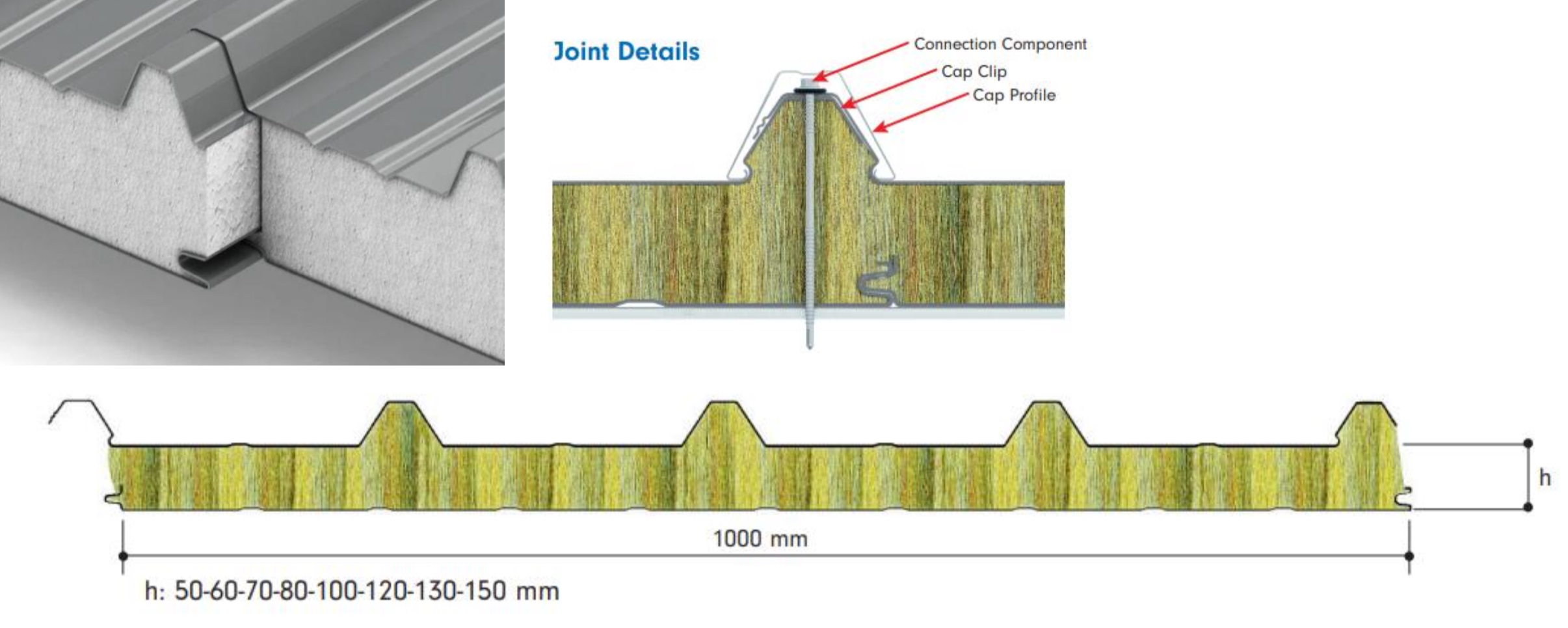

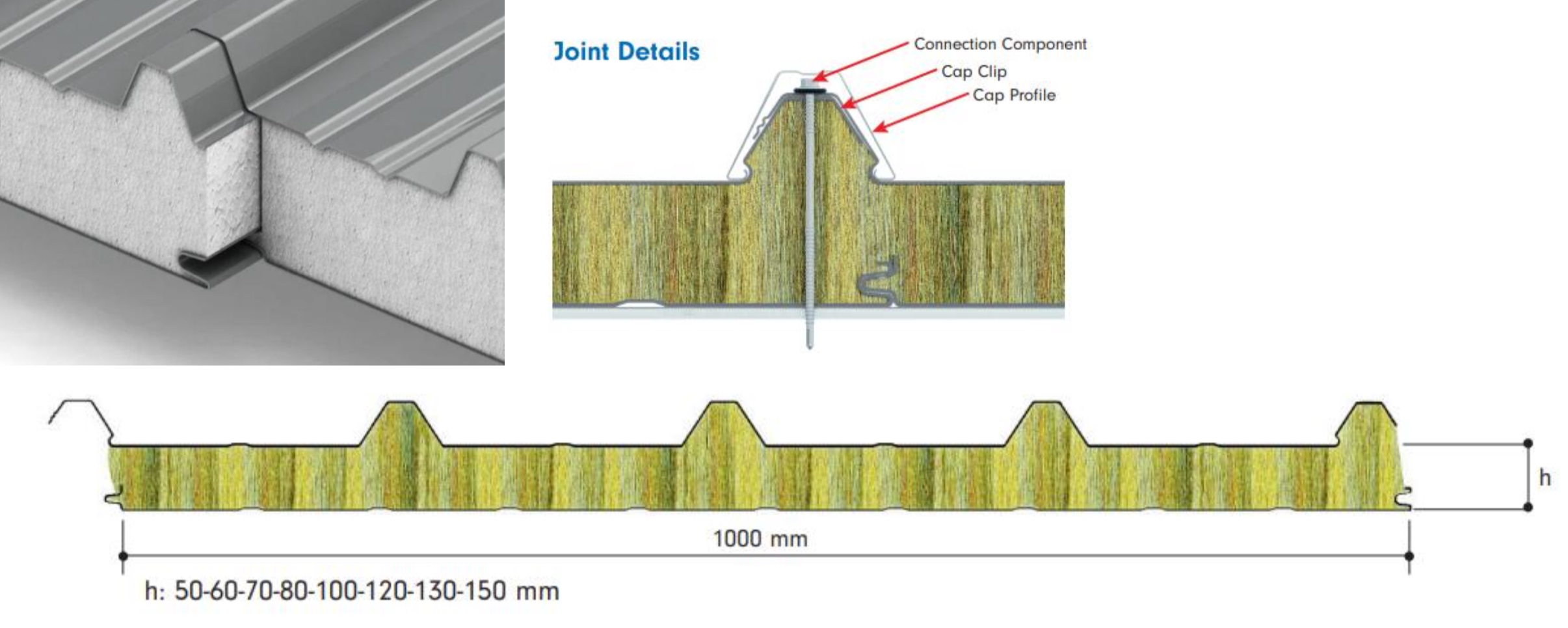

Xinnuo’s Rock Wool Sandwich Panels Production Line specializes in high-performance roof panels, and can be configured to produce wall panels per project requirements. Our latest roof + wall integrated line offers seamless switching between panel types. “Z-lock” lapping is our primary joint system; standard lap is also offered.

Xinnuo’s Rock Wool Sandwich Panels Production Line specializes in high-performance roof panels, and can be configured to produce wall panels per project requirements. Our latest roof + wall integrated line offers seamless switching between panel types. “Z-lock” lapping is our primary joint system; standard lap is also offered.

This cutting-edge production line, built with internationally recognized technology, offers a highly efficient and cost-effective way to produce high-quality composite roof panels, making it the ideal choice for businesses in the roofing industry.

Sandwich panels represent a modern innovation that has transformed the construction of rooms or halls requiring strictly controlled environments—most importantly, effective thermal insulation.

A sandwich panel consists of a core insulating material trapped between two sheets of galvanized steel or aluminum, delivering both thermal and acoustic insulation; certain panel types also offer excellent fire resistance.

They are called “sandwich panels” because, like a sandwich, they comprise three layers: two outer metal facings and a middle insulating layer.

The core layer is the insulating material—typically rigid polyurethane, polyisocyanurate, mineral wool, or rock wool, or a composite blend of these—manufactured at a density of 40 ± 2 kg/m³.

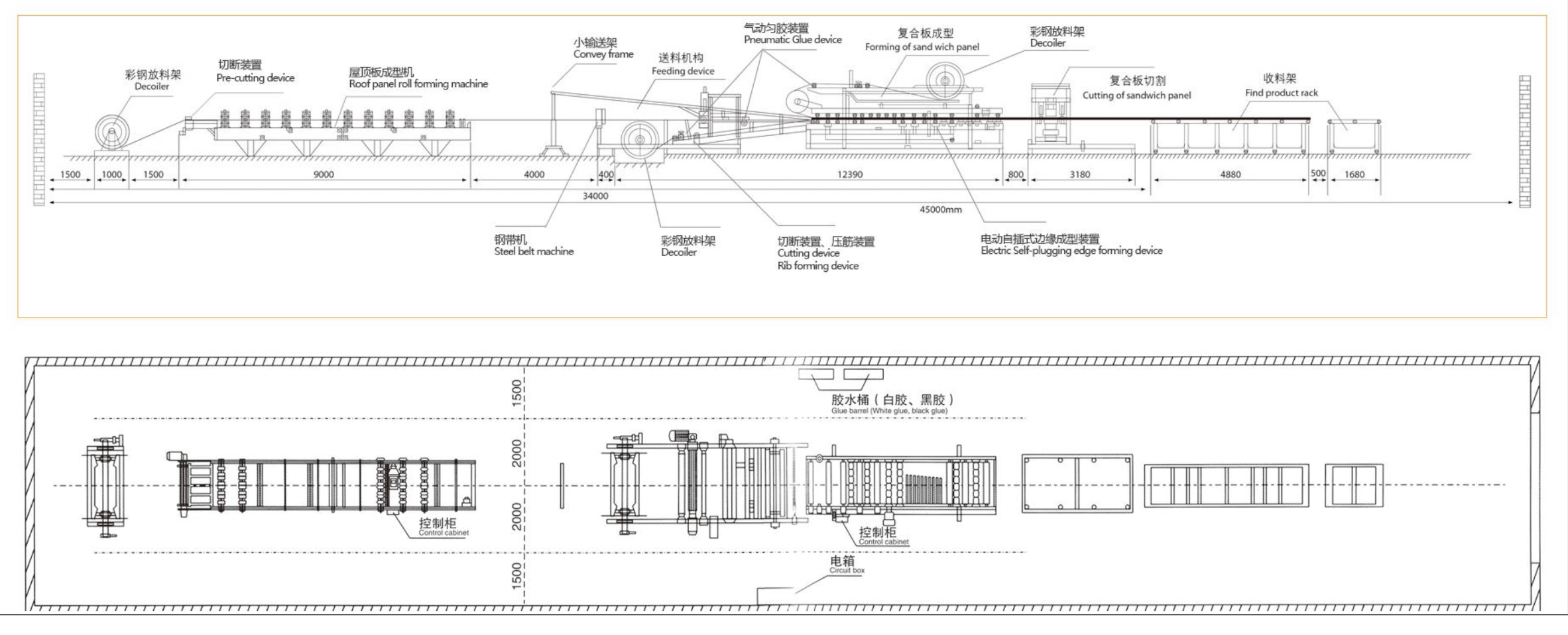

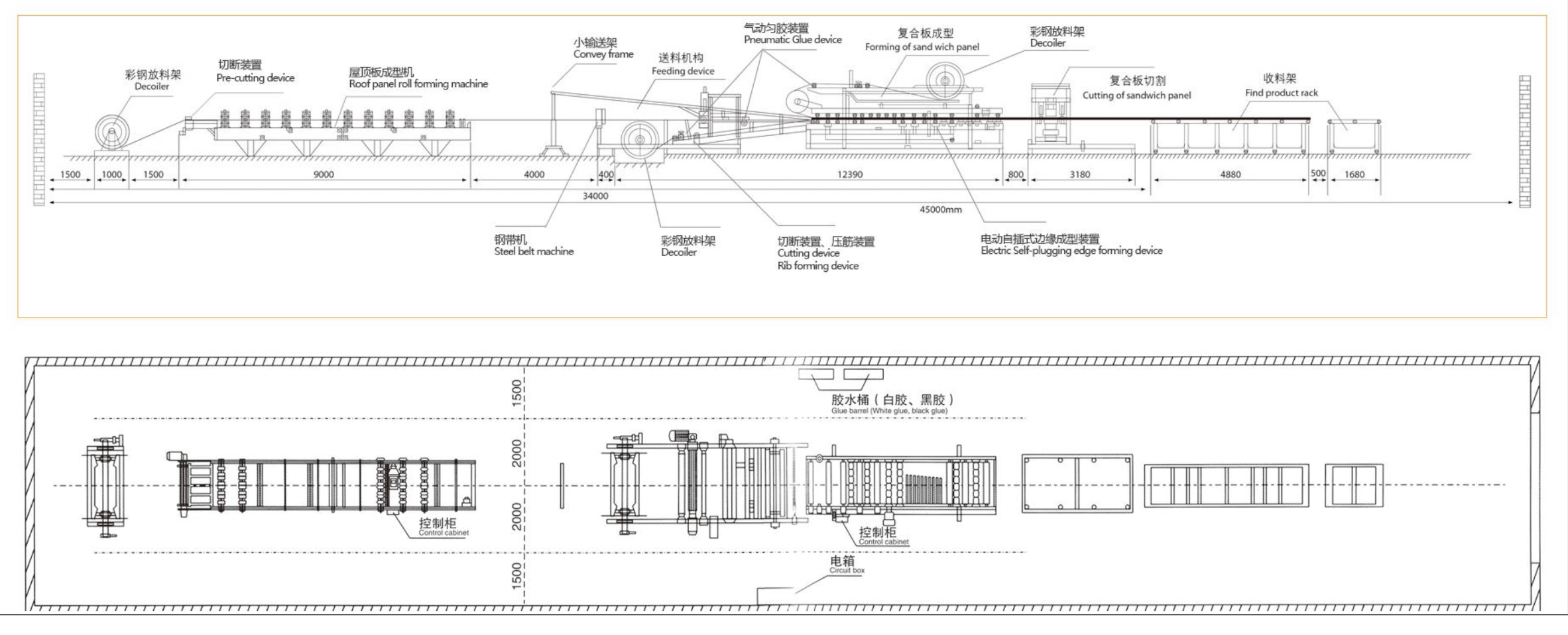

This versatile production line combines efficiency, flexibility, and cost-effectiveness, making it the ideal choice for businesses seeking high-quality sandwich panels in a streamlined, space-saving production process.

The Sandwich Panel Production Line is a complete, high-efficiency manufacturing solution designed to help businesses start producing sandwich panels from scratch. This fully integrated system includes all the necessary machines, tools, and accessories required for panel production, reducing the need for separate purchases and optimizing sea freight costs.

CAN U IMAGINE a PRODUCTION LINE filled with LEADING TECH?

HERE it is, in XINNUO!

One of the major advantages of our production line is its advanced automation technology. Equipped with internationally leading machinery, the system operates with a high degree of automation, ensuring precise manufacturing and minimizing manual labor. This results in higher production efficiency, improved product consistency, and reduced operational costs.